Power Range2320-2722 bhp (1730-2030 bkW)

Speed Range900-1000 rpm

EmissionsIMO II

AspirationTA

Bore11in

Stroke11.8in

Displacement6773in³

Rotation from Flywheel EndCounterclockwise or clockwise

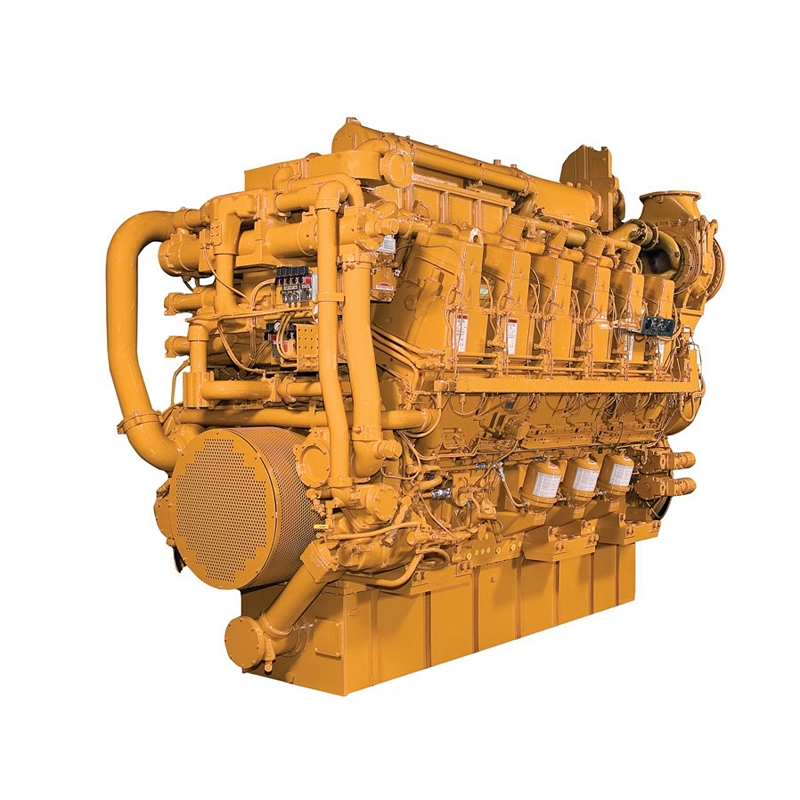

ConfigurationIn-line 6, 4-Stroke-Cycle Diesel

Dry Weight34496lb

Length158in

Width71in

Height108in