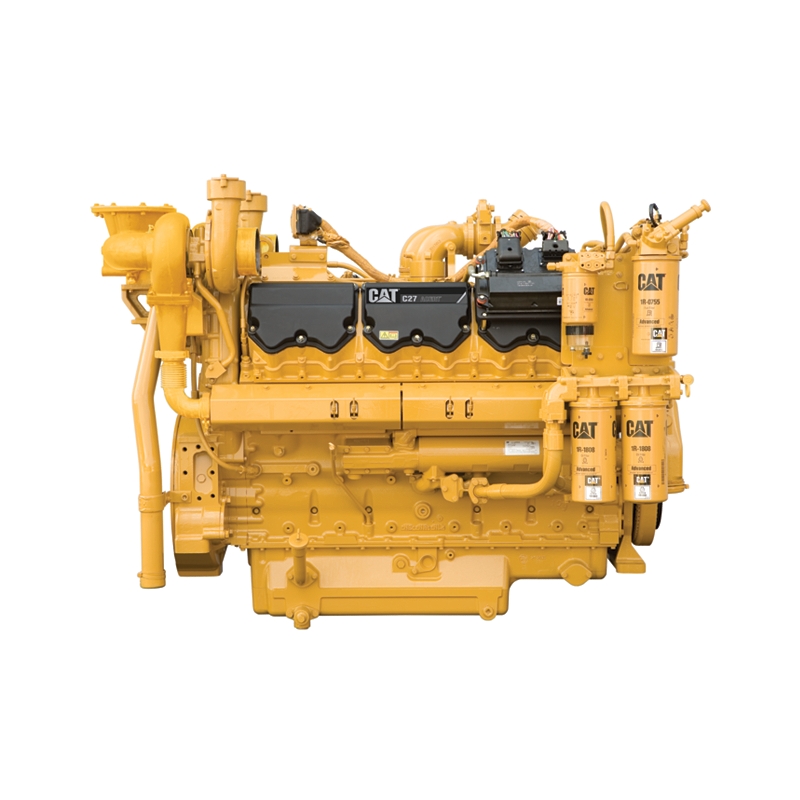

Maximum Rating1150BHP

EmissionsU.S. EPA Non-road Tier 2

Displacement1658in³

Minimum Rating800BHP

Bore5.42in

Stroke6in

AspirationTurbocharged-Aftercooled

Governor and ProtectionADEM A3

Engine Weight - Net Dry6382lb

Oil Change Interval250

Rotation from Flywheel EndCounterclockwise

Flywheel and Flywheel HousingSAE No. 0 or SAE No. 1

Flywheel Teeth136 (SAE 0), 113 (SAE 1)

Minimum Cooling System - Engine Only14.5gal (US)

Length75.5in

Width57.6in

Height52in