Engine Output - SAE J19951649hp

Bucket Payload33ton (US)

Operating Weight324ton (US)

NoteSpecifications shown above apply to the highly regulated Face Shovel configuration. Backhoe and Frontless configurations are also available for all regions.

Gross Power - SAE J19951649hp

Net Power - ISO 92491625hp

Net Power - SAE J13491541hp

EmissionsMeets U.S. EPA Tier 4 Final and EU Stage V emission standards

Gross Power - SAE J19951531hp

Net Power - SAE J13491425hp

Net Power - ISO 92491511hp

EmissionsMeets China Nonroad Stage III emission standards, equivalent to U.S. EPA Tier 2

Number of Cylinders - Each Engine12

Bore5.42in

Stroke6in

Displacement1648in³

AspirationTurbocharged and air-to-air aftercooled

Components (1)Hydraulically driven radiator fan with electronically controlled fan speed

Components (2)Micro processed engine management

Components (3)Heavy-duty air filters

Components (4)Two-stage fuel filter, including water separator

Components (5)Additional high-capacity water separator

EmissionsMeets U.S. EPA Tier 4 Final and EU Stage V emission standards

Fuel Tank Capacity1342gal (US)

System Voltage24V

Batteries in Series/Parallel Installation4 x 210 Ah at 12V each; 420 Ah with 24V in total

Components (1)Battery isolation relays

Components (2)Emergency stop switches accessible from ground level and in engine module

Components (3)14 LED high-brightness working flood lights

Components (4)11 LED service lights

Batteries4 maintenance-free batteries

6030 FS - Standard Track Pads3.25ft

6030 FS - Operating Weight657640lb

6030 FS - Ground Pressure32.2psi

6030 - Standard Track Pads3.25ft

6030 - Operating Weight660060lb

6030 - Ground Pressure32.3psi

NoteOther track pads available on request. Operating weights include: base machine, front attachment, standard track pads, standard rock bucket, and 100% fuel and lubricants.

Hydraulic Tank Capacity - Approximately707gal (US)

Total Volume of Hydraulic Oil - Approximately925gal (US)

Main Pumps4 x variable swash plate pumps

Main Pumps - Maximum Oil Flow - Diesel Version4 x 552 L/min (4 x 146 gal/min)

Maximum Pressure - Attachment4495psi

Maximum Pressure - Travel5220psi

Swing Pumps2 x reversible swash plate double pumps

Swing Pumps - Maximum Oil Flow - Diesel Version4 x 197 L/min (4 x 52 gal/min)

Maximum Pressure - Swing Pumps5076psi

Oil Flow of Cooling Pumps - Diesel Version2 x 467 L/min (2 x 123 gal/min)

Diameter - Fan48in

Swing Drive2 compact planetary transmissions with axial piston motors

Parking BrakesWet multiple-disc brake, spring-loaded/hydraulically released

Maximum Swing Speed - Diesel Version4.6r/min

Swing RingTriple-race roller bearing with sealed internal gearing

Maximum Swing Speed - AC Version5r/min

Travel Speed - 1st Stage - Maximum0.87mile/h

Travel Speed - 2nd Stage - Maximum1.68mile/h

Maximum Tractive Force360144ft·lbf

Gradeability - Travel Drives - Approximate47%

Track Pads - Each Side44

Bottom Rollers - Each Side7

Support Rollers - Each Side2 plus a skid plate in between

Travel Drives - Each Side1 planetary transmission with 2 two-stage axial piston motors

Parking BrakesWet multiple disc brake, spring loaded/hydraulically released

Components (1)All running surfaces of sprockets, idlers, rollers and pad links, as well as teeth contact areas of sprocket and pad links, are hardened

Components (2)Cast double-grouser combined pad-links with bushings connected by hardened full floating pins

Components (3)Fully hydraulic self-adjusting track tensioning system with membrane accumulator

Components (4)Automatic hydraulic retarder valve to prevent over-speed on downhill travel

Components (5)Acoustic travel alarm

Operator's Eye Level - Approximately21.33ft

Internal Dimensions of Cab - Length7.22ft

Internal Dimensions of Cab - Width5.25ft

Internal Dimensions of Cab - Height7.05ft

Components (1)Under roof mounted heating ventilating and air conditioning system

Components (2)External sun shields at side and rear windows

Components (3)Robust instrument panel including large colored BCS screen with transflective technology

Components (4)Board Control System (BCS) electronic monitoring and data logging system for vital signs and service data of engines, hydraulic system and lubrication system

Components (5)Hydraulically operated 45 degree access stairway

Components (6)Emergency egress ladder with ladder cage

Components (7)Switch in seat cushion to automatically neutralize the hydraulic controls when operator leaves the seat

Components (8)Pneumatically cushioned and multi-adjustable comfort seat with lumbar support, seat heating, safety belt, head- and armrests

Components (9)Roller blinds at all windows

Components (10)Windshield with parallel intermittent wiper/washer

Components (11)All-round safety glass, armored windshield and sliding side window

Components (12)Operator Protective Guards (ISO 10262:1998 Level II

Components (13)Joystick controls integrated in independently adjustable seat consoles

Components (14)Fold-away auxiliary seat with safety belt

Capacity - Grease Container119gal (US)

Type (1)Dual-circuit system with hydraulically driven heavy-duty pump and electronic time relay control to adjust the pause/lube times

Type (2)Connected to the lubrication system are the swing roller bearing with internal gearing and all pivot points of attachment, bucket and cylinders

Type (3)Lubricated pinion for greasing of internal gearing of swing ring

Type (4)System failures displayed by Board Control System

Type (5)Grease filters between service station and container as well as directly behind grease pump

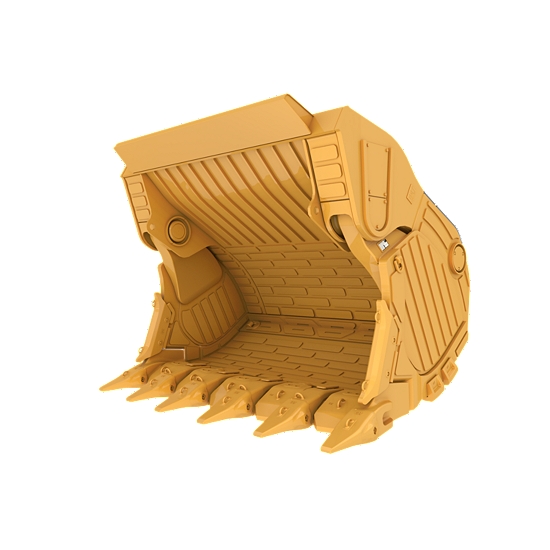

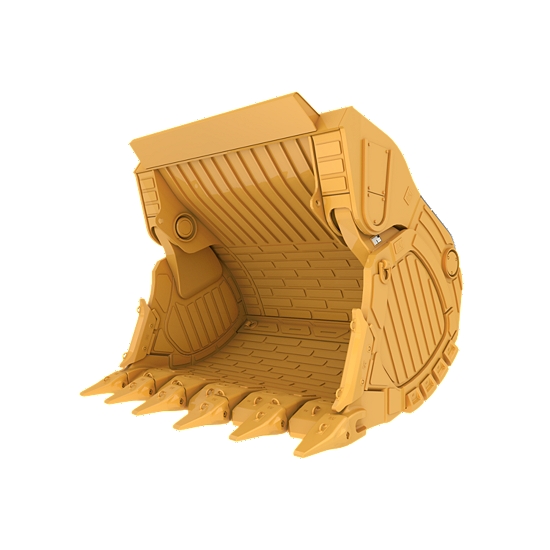

Bucket Capacity - Face Shovel (heaped 2:1)21.6yd³

Bucket Capacity - Backhoe (heaped 1:1)22.2yd³

Maximum Crowd Force291700ft·lbf

Maximum Tearout Force212150ft·lbf

Shovel attachment with unique TriPower kinematics ensuring the following main features: (1)Automatic roll-back limiter to prevent material spillage and kinematic assistance to hydraulic forces

Shovel attachment with unique TriPower kinematics ensuring the following main features: (2)Horizontal automatic constant-angle bucket guidance and vertical automatic constant-angle bucket guidance

Shovel attachment with unique TriPower kinematics ensuring the following main features: (3)Constant boom momentum throughout the whole lift arc and crowd force assistance

All buckets (FS and BH) are equipped with a wear package consisting of: (1)Special liner material covering main wear areas inside and outside of bucket and lip shrouds between teeth

All buckets (FS and BH) are equipped with a wear package consisting of: (2)Wing shrouds on side walls and heel shrouds at bottom edges

Type (1)Catwalks with rails at booms

Type (2)Special wear packages for highly abrasive materials on request

Type (3)Pressure-free lowering of boom (FS and BH) and stick (FS) by means of a float valve

Type (4)Welding procedures allow for internal counter-welding (double prep weld) wherever possible

Type (5)Booms and sticks are stress-relieved after welding

Type (6)Booms and sticks are torsion-resistant, welded box design of high-tensile steel with solid steel castings at pivot areas