Net Power541HP

Engine ModelCat® C18 ™

Bore5.7in

Stroke7.2in

Displacement1105in³

Torque Rise58%

Rated Speed1700/min

Peak Torque - 1,200 rpm2104lb/ft

Net Power - SAE J1349541HP

Peak Power Speed1500/min

Peak Power Speed - 1,500 rpm - Gross - ISO 14396580HP

Gross - ISO 14396580HP

Peak Power Speed - 1,500 rpm - Gross - SAE J1995588HP

EmissionsU.S. EPA Tier 4 Final/EU Stage V OR Tier 3/Stage IIIA Equivalent OR Tier 2/Stage II Equivalent

Peak Power Speed - 1,500 rpm - Net Power - SAE J1349541HP

Operating Weight112574lb

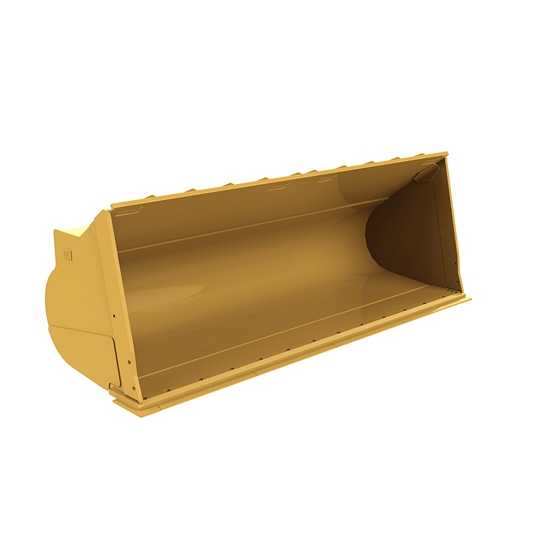

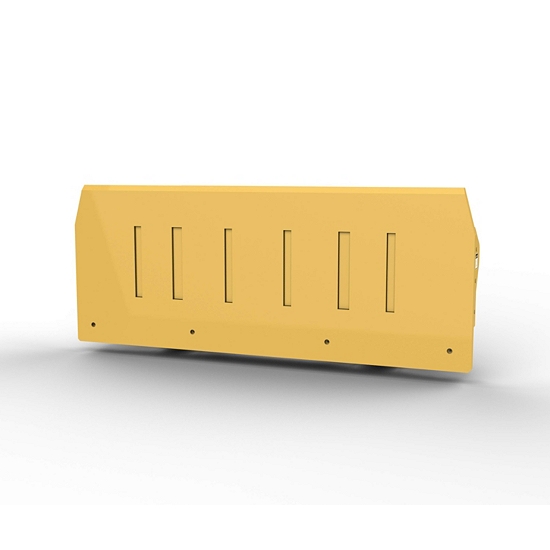

Bucket Capacity Range4.7-13 m3 (6.2-17 yd3)

Rated Payload - Quarry Face12.5t

Cat Truck Match - High Lift773~775

Rated Payload - Loose Material16t

Cat Truck Match - Standard770~772

Bucket Capacities4.7-13 m3 (6.2-17 yd3)

Transmission TypeCat-Planetenlastschaltgetriebe

Forward - 14mile/h

Forward - 27.2mile/h

Forward - 312.7mile/h

Forward - 421.6mile/h

Reverse - 14.7mile/h

Reverse - 28.3mile/h

Reverse - 314.4mile/h

Direct Drive - Reverse 28.9mile/h

Direct Drive - Reverse 315.8mile/h

Direct Drive - Forward 27.8mile/h

Direct Drive - Reverse 15mile/h

Direct Drive - Forward 1Lock-up disabled

Direct Drive - Forward 313.9mile/h

Direct Drive - Forward 424.4mile/h

FrontFixed

RearTrunnion

Oscillation Angle13 °

Fuel Tank188gal (US)

Cooling System31.7gal (US)

Crankcase15.9gal (US)

Transmission31.7gal (US)

Hydraulic System - Tank Only63.4gal (US)

Differential - Final Drives - Rear49.1gal (US)

Hydraulic System Factory Fill125.5gal (US)

Diesel Exhaust Fluid Tank (For Tier 4 Final/Stage IV Only)8.7gal (US)

Differential - Final Drives - Front49.1gal (US)

Coolant (Validated by Test Cell Fill Quantities)33gal (US)

Transmission - Validated by Test Cell Fill Quantities29gal (US)

Maximum Flow13.7gal/min

Maximum Flow at 1,400-1,860 rpm153gal/min

Lift/Tilt SystemVariable displacement piston

Cylinders, Double Acting - Tilt, Bore and Stroke269 mm × 685 mm (8.7 in × 27 in)

Relief Valve Setting - Main551psi

Relief Valve Setting - Lift/Tilt4757psi

Pilot SystemVariable displacement piston

Cylinders, Double Acting - Lift, Bore and Stroke210 mm × 1050 mm (8.7 in × 41.3 in)

Lift/Tilt System - CircuitEH- Positive Flow Control, Flow Sharing

Steering System - PumpPiston, variable displacement

Total Steering Angle86 °

Maximum Flow71.3gal/min

Relief Valve Setting - Steering4351psi

Steering Cycle Times - High Idle3.4s

Steering System - CircuitPilot, load sensing

Steering Cycle Times - Low Idle5.6s

Total Hydraulic Cycle Time - Empty Bucket18.2s

Lower Float Down3.5s

Rack Back4.5s

Raise8s

Dump2.2s

Operator Sound Level (ISO 6396)72dB(A)

Machine Sound Level (ISO 6395)111dB(A)

Machine Sound Level (ISO 6395)109dB(A)

Operator Sound Level (ISO 6396)72dB(A)

Operator Sound Level (ISO 6396)72dB(A)

Machine Sound Level (ISO 6395)110dB(A)

Machine Sound Level (ISO 6395)112dB(A)

Operator Sound Level ( ISO 6396)73dB(A)

BrakesSAE J1473 OKT90, ISO 3450:1992