Net Power973HP

Operating Weight294687lb

Operating Weight - Tier 2 Equivalent*294687lb

Rated Payload - High Lift27.5t

Operating Weight*294687lb

Cat Truck Match - Standard Lift777

Operating Weight - Tier 4 Final*294687lb

Rated Payload - Standard Lift30t

Cat Truck Match - High Lift777, 785

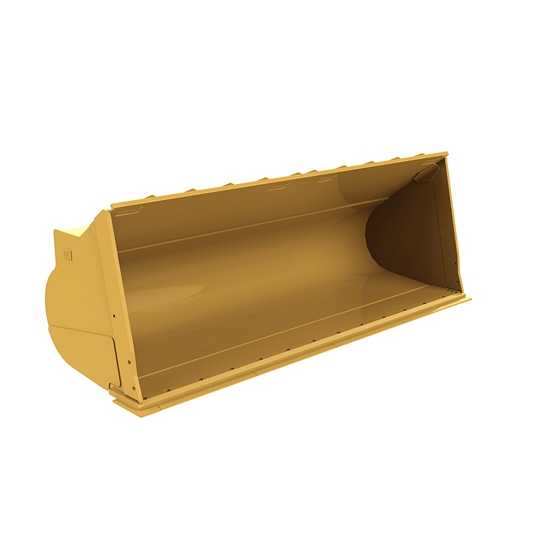

Bucket Range12.2-23.7 m3 (16.0-31.0 yd3)

Note* High lift, 60/65-51 BFOR (311-1938), standard cooling, 13.8 m3 (18.0 yd3) bucket (496-9912).

Articulation Angle43°

Bucket Capacities12.2-23.7 m3 (16.0-31.0 yd3)

Transmission TypeCat Planetary Power Shift

Forward - 14.2mile/h

Forward - 27.4mile/h

Forward - 312.7mile/h

Reverse - 14.7mile/h

Reverse - 28.1mile/h

Reverse - 313.9mile/h

Direct Drive - Reverse 315.6mile/h

Direct Drive - Reverse 14.9mile/h

Direct Drive - Reverse 28.8mile/h

Direct Drive - Forward 314.1mile/h

Direct Drive - Forward 28mile/h

Direct Drive - Forward 1Lock-up disabled

Note50/65-51 BFOR (311-1938), calculated speeds.

FrontFixed

RearTrunnion

Oscillation Angle10 degrees

Fuel Tank573.3gal (US)

Cooling System80.2gal (US)

Crankcase31.7gal (US)

Transmission52gal (US)

Hydraulic System - Tank Only146gal (US)

Differential - Final Drives - Front127.3gal (US)

Differential - Final Drives - Rear127.3gal (US)

Hydraulic System Factory Fill230gal (US)

NoteHigh Lift configuration.

Lift/Tilt System - PumpVariable Piston

Cylinders - Lift/TiltDouble-acting

Relief Valve Setting - Lift/Tilt4200psi

Maximum Flow at 1,650 rpm311gal/min

Tilt Cylinder - Bore9.3in

Lift Cylinder - Bore10.5in

Lift/Tilt System - CircuitPositive Flow Control

Lift Cylinder - Stroke66.2in

Tilt Cylinder - Stroke40.9in

NoteHigh Lift configuration.

Lower3.8s

Rack Back2.4s

Lower Float Down3.1s

Total Hydraulic Cycle Time17.2s

Dump1.8s

Raise9.2s

NoteHigh Lift configuration, calculated speeds.

Total Steering Angle86°

Maximum Flow at 1,985 rpm (6900 kPa/1,000 psi)133gal/min

Relief Valve Setting - Steering5000psi

Steering System - CircuitClosed

Steering System - PumpPiston, variable displacement

Stroke6.4in

Displacement1959in³

Peak Torque - 1,250 rpm4034lb/ft

Net Power - EEC 80/1269973HP

Net Power - SAE J1349964HP

Gross Power - SAE J19951039HP

Bore5.7in

Rated Speed1800r/min

Net Power - ISO 9249973HP

Torque Rise33%

Net Power - ISO 143961024HP

EmissionsU.S. EPA Tier 4 Final

Engine ModelCat® C32 with ACERT™ Technology

NoteStandard ambient cooling.

Stroke6.4in

Gross Power - SAE J19951041HP

Peak Torque - 1,250 rpm4034ft-lb

Net Power - EEC 80/1269973HP

Bore5.7in

Net Power - ISO 143961024HP

Rated Speed1800r/min

Net Power - ISO 9249973HP

Displacement1959in³

Net Power - SAE J1349964HP

EmissionsU.S. EPA Tier 2 Equivalent

Torque Rise33%

Engine ModelCat C32 with ACERT Technology

NoteStandard ambient cooling.

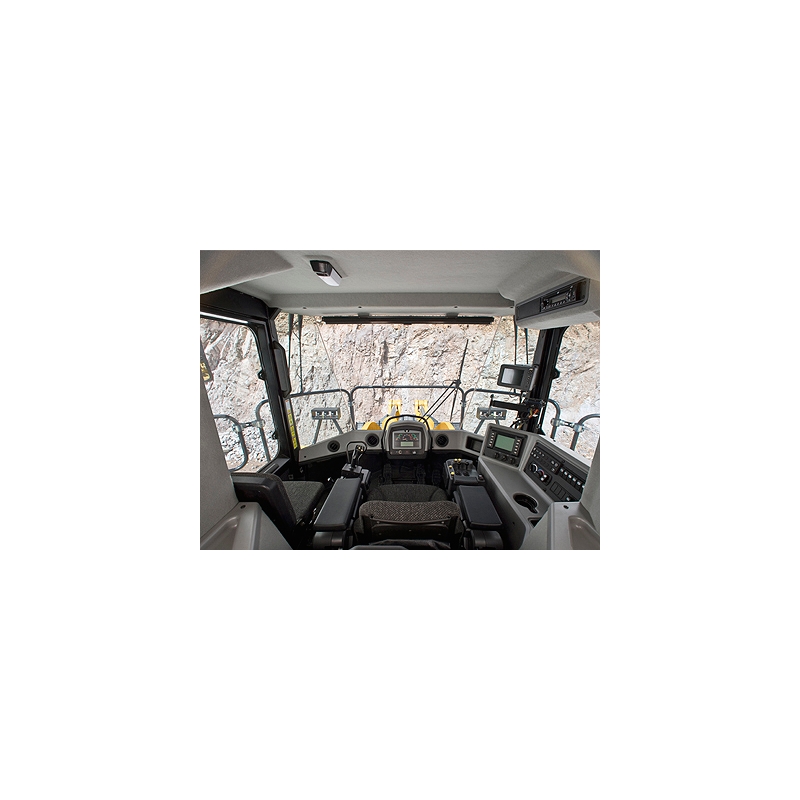

Operator Sound Pressure - ANSI/SAE J1166 FEB0872dB(A)

Dynamic Operator Sound Pressure Level (ISO 6396:2008)70dB(A)

Note (1)Hearing protection may be needed when the machine is operated with a cab that is not properly maintained or when the doors or windows are open for extended periods or in a noisy environment. Hearing protection may be needed when the machine is operated wi

Note (3)The machine sound power level is 113 dB(A), measured according to the test procedures and conditions specified in ISO 6395:2008 for the sound suppressed machine configuration. The measurement was conducted at 70 percent of the maximum engine cooling fan s

Note (2)The machine sound power level is 116 dB(A), measured according to the test procedures and conditions specified in ISO 6395:2008 for the standard machine configuration. The measurement was conducted at 70 percent of the maximum engine cooling fan speed.