Standard

Speed adjust

Text alarm/event descriptions

Generator set packages include Caterpillar's voltage regulator

Auto/start/stop control

24 Volt DC operation

Cat ECS 100

Generator mounted - Rear facing

Controls:

Environmental sealed front face

Engine cool-down timer

Emergency stop pushbutton

Limiter and exciter diode monitor

Engine cycle crank

Lamp test

Alarm acknowledge

Customizable screens

PLC functionality

Load histogram feature

0 True RMS AC metering, 3-phase, +/-2% accuracy

Operating hours

Digital indication for:

DC volts

RPM

Coolant temperature

Amps (per phase & average)

Oil pressure (psi, kPa or bar)

Volts (L-L & L-N)

Frequency (Hz)

Power factor (per phase & average)

kW (per phase, average & percent)

High coolant temperature

Low oil pressure

Warning/shutdown with common LED indication of shutdowns for01/10/2018:

kVAr (per phase, average & percent)

kVA (per phase, average & percent)

kVAr (per phase, average & percent)

Emergency stop

Overspeed

Failure to start (overcrank)

Programmable protective relaying functions:

Low coolant temperature

Generator phase sequence

Low coolant level

1 Programmable digital outputs

Gear type lube oil pump

Battery disconnect switch

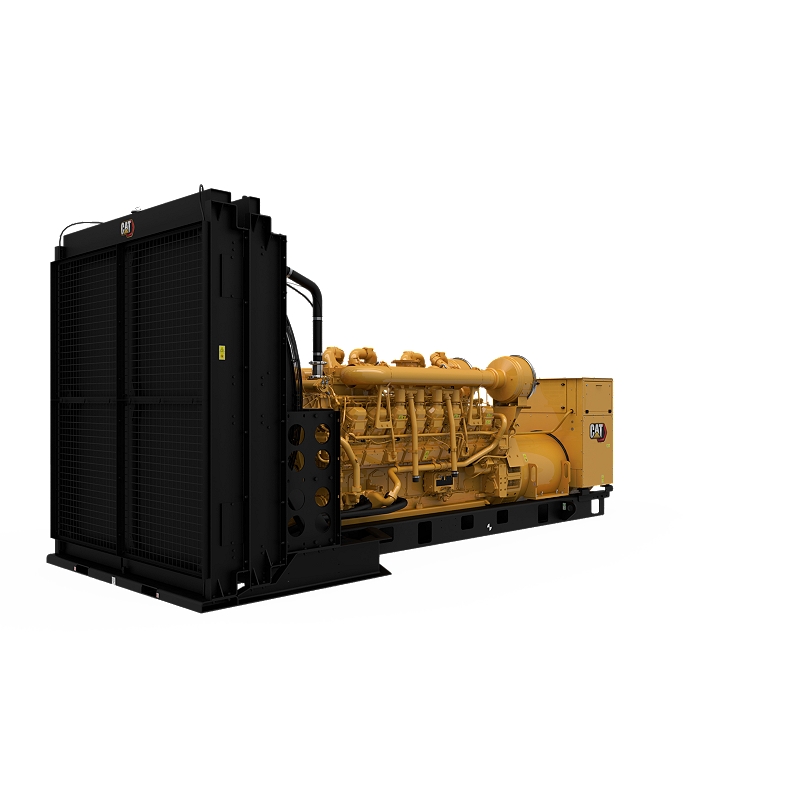

Caterpillar yellow with high gloss black rails and radiator

NEMA Class H insulation system, Class H temperature rise at 40C ambient (125C prime / 150C standby)

Medium voltage: Form wound - Permanent magnet excitation (PMG) - Winding temperature detectors - NEMA Class H insulation system, Class H temperature rise at 40C ambient

(125C prime / 150C standby) - Busbar connections, right side extension box, bottom cable entry - NEMA standard hole pattern

Fumes disposal

Permanent magnet excitation (PMG)

NEMA Class H insulation system, Class H temperature rise at 40C ambient (125C prime / 150C standby)

Permanent magnet excitation (PMG)

NEMA standard hole pattern

Reverse reactive power (kVAr) (32RV)

Over/under voltage (27/59)

NEMA Class H insulation system, Class H temperature rise at 40C ambient (125C prime / 150C standby)

Permanent magnet excitation (PMG)

Class H insulation, Class F temperature rise at 40C ambient (105C prime / 130C standby)

Permanent magnet excitation (PMG)

SAE standard rotation

Internal excitation (IE)

Flexible fuel lines - shipped loose

IVR includes reactive droop capability, 3-phase voltage sensing, KVAR/PF modes, RFI suppression, min / max exciter

Busbar connections, right side extension box, bottom cable entry

Medium voltage:

Communications:

NEMA standard hole pattern

Lubricating oil

Oil drain lines and valve

3 Phase brushless, Salient pole

24 Volt electric starting motor

6 Customer programmable digital inputs

Dry exhaust manifold

Accessory module data link

ADEM A3

Form wound

ATAAC - 3516E package radiators shipped installed

Busbar connections, top center mounted, top cable entry

High voltage:

4 Programmable relay outputs (Form A)

Anti-condensation space heater

NEMA Class H insulation system, Class H temperature rise at 40C ambient (125C prime / 150C standby)

Controls: Speed adjust - Auto/start/stop control - Engine cool-down timer - Engine cycle crank - Alarm acknowledge - Lamp test - Load histogram feature - PLC functionality - Customizable screens -0 True RMS AC metering, 3-phase, +/-2% accuracy

NEMA standard hole pattern

45 Amp Charging alternator

3 Analog inputs

Random wound

Anti-vibration mounts (shipped loose)

Cat connect

Oil filter, filler and dipstick

Rails - Engine/generator/radiator mounting

Customer data link (Modbus RTU)

Flywheel and flywheel housing - SAE No. 00

English

Busbar connections, right side extension box, bottom cable entry

Serial annunciator module data link

Integral lube oil cool

Certified standard PGS provided

Winding temperature detectors

1 Programmable relay outputs (Form C)

Reverse power (kW) (32)

Form wound - Permanent magnet excitation (PMG)

Right hand servicing

Overcurrent (50/51)

6 Lead

Flanged faced outlet(s)

Low voltage:

Number of I/O varies on options selected

Battery and battery rack w/cables

Over/under frequency (81 o/u)

Fuel cooler; not included with packages without radiator

Busbar connections, right side extension box, bottom cable entry

Rubber anti-vibration mounts - shipped loose

NEMA standard hole pattern

Optional

Generator temperature monitoring & protection

Remote monitoring software

Load share module

Digital I/O module