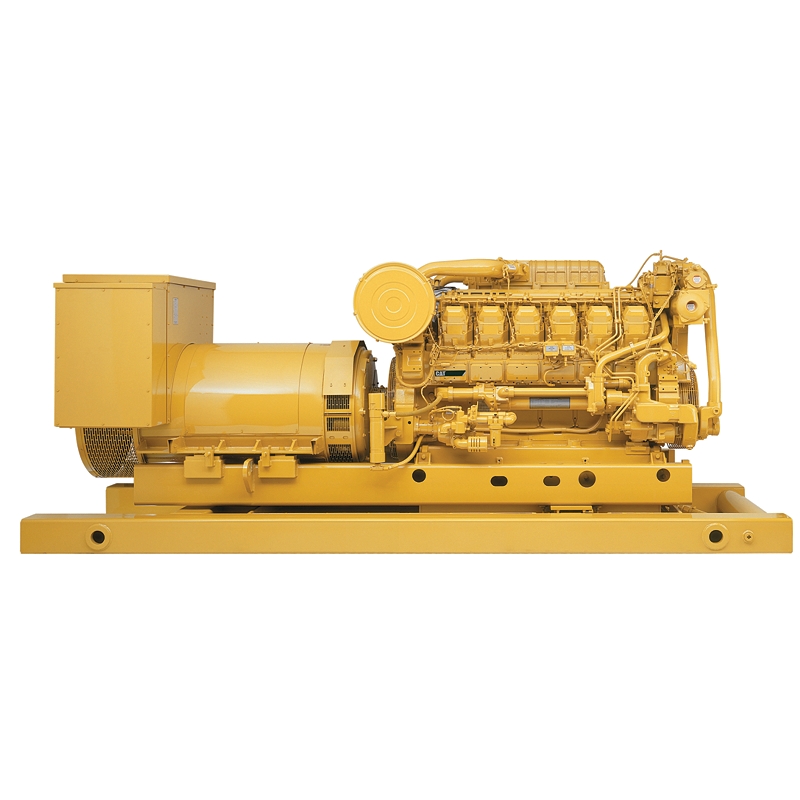

Minimum Rating1100kV·A

Maximum Rating1943kV·A

EmissionsIMO Tier I

Weight33014lb

Stroke7.5in

Displacement3175in³

Bore6.7in

Oil Change Interval1000h

Engine ControlADEM A3

AspirationTurbocharged-Aftercooled

Fuel SystemEUI

Height86.9in

Length190.6in

Width78.3in

Cooling System - Engine106gal (US)

Lube Oil System - Refill84gal (US)