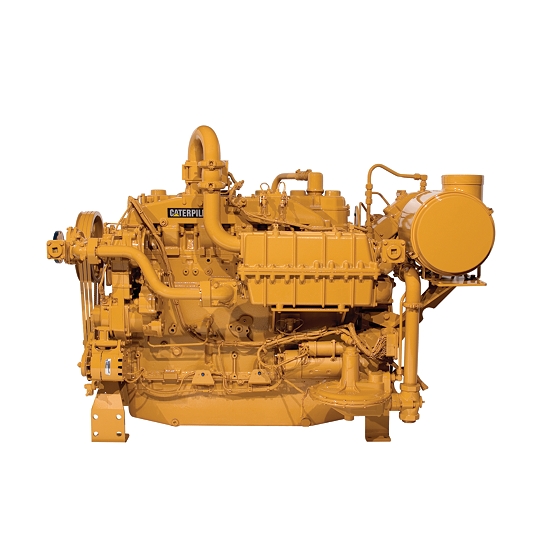

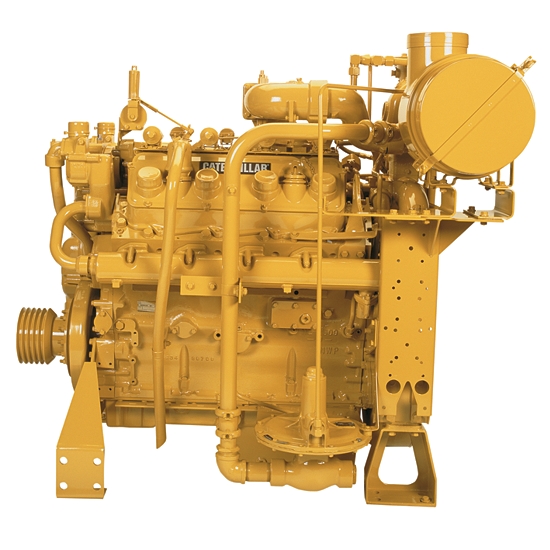

Maximum Rating600BHP

Rated Speed1800rpm

EmissionsRich Burn: Standard Emissions for Export Only

Minimum Rating600BHP

Displacement1649in³

Compression Ratio9.7:1

AspirationTurbocharged - Aftercooled

Rotation from Flywheel EndCounterclockwise

Flywheel and Flywheel HousingSAE No. 0

Flywheel Teeth136

Weight - Dry4720lb

Oil Change Interval750 hours

Ignition, ProtectionAltronic III

Stroke6in

Bore5.4in

Cooling System20gal (US)

Lube Oil System - Refill45gal (US)